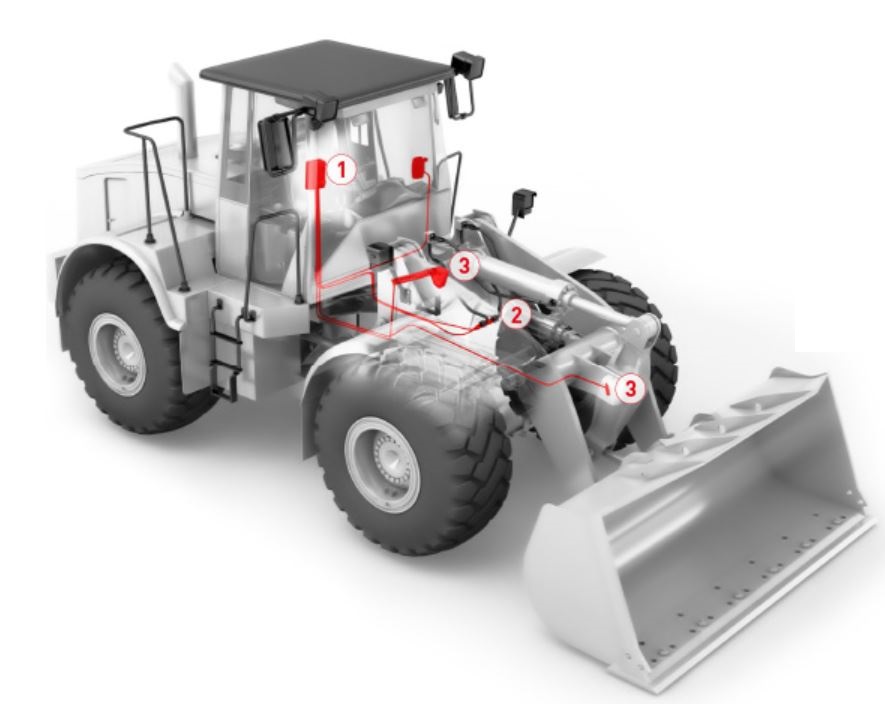

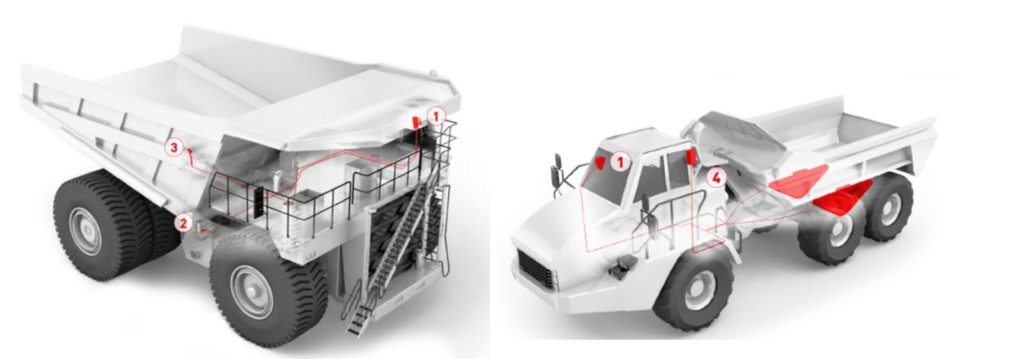

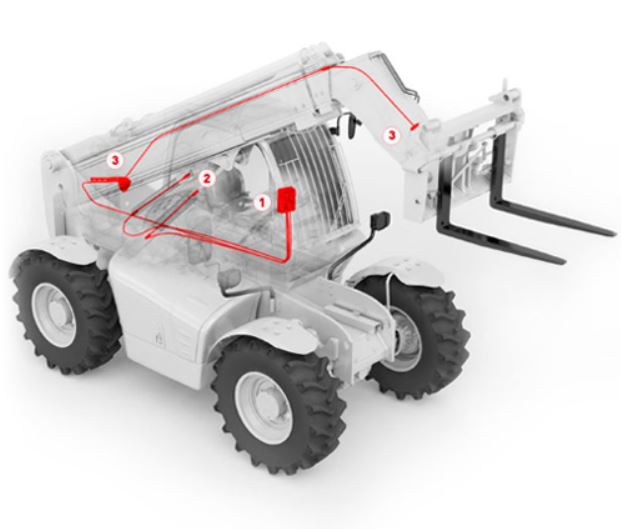

Pesage embarqué sur chargeur sur pneus

- 2 jauges de pression mesurent la pression hydraulique de part et d’autre du piston dans les vérins de levage, soit dynamiquement durant le levage, soit statiquement à l’arrêt;

- Insensible à la vitesse de levage qui est mesurée par un double capteur de position situé à proximité du pivot du bras de levage.

- Montage réalisé intégralement par nos soins en vos ateliers, sur toute machine, petite ou grande, neuve ou âgée, de toute marque.

- Sa longévité excède celle de la machine: nous transférons très souvent nos systèmes de pesage sur des machines neuves. Les microprocesseurs PFREUNDT WK60-XS, WK60-Smart, WK60-S ou WK60 ont les caractéristiques communes suivantes:

+ Précision: 1%

+ Cumul de pesages successifs

+ Soustraction d’un poids cible

+ Approche aisée du poids cible correct dans le dernier godet

+ Touche de mise en stand-by: les pesages sont temporairement suspendus

+ Ecran couleur avec clavier alfanumérique tactile.

Les nombreuses possibilités sur WK60X-S, WK60-SMART, WK60-S et WK60 telles que décrites ci-dessus, peuvent être activées ou désactivées lors de l’installation, afin de répondre au mieux à vos besoins.

Notre valise de démonstration vous démontrera les nombreuses possibilités et la facilité d’usage.

| Type | WK60-XS | WK60-Smart | WK60-S | WK60 |

|---|---|---|---|---|

| Taille de l’écran | 7″ | 7″ | 7″ | 7″ |

| Poinçonnable classe Y(b), autorisé pour matériaux de construction, minerais et certains déchets | non | oui | oui | oui |

| Calibration pour x godets maximum, non poinçonnable | 2; 5 en option | 5 | 5 | 5 |

| Imprimante sur bordereaux ou bobines | bordereaux | bordereaux | oui | oui |

| Mise en page de l’imprimante modifiable | oui | oui | oui | oui |

| Gestion des totaux journalier, hebdomadaire, mensuel, annuel ou éternel | uniquement journalier |

oui | oui | oui |

| Statistiques pour une ou plusieurs données de base | non | non | oui | oui |

| Base de données + clients avec leur nom, adresse, téléphone, notes, modes de paiement, + matériaux avec leur nom, densité, prix et note, + chauffeurs avec leur nom, + camions avec leur nom et charge maxi, + chantiers avec leur nom et adresse + conteneurs avec leur nom |

10, en option 300 |

10 | 500 | 10.000 |

| Mémoire des xxx pesages | 250, en option 1000 | 100.000 | 100.000 | 100.000 |

| Mémoire alibi | non | non | oui | oui |

| Affichage et impression du cubage | non | non | oui | oui |

| Bordereau avec mention du prix et calcul de la TVA pour les clients payant comptant | non | non | oui | oui |

| Protocol sériel | non | oui | non | oui |

| Bordereaux de pesage cumulant des pesages répétitifs mais non successifs, par exemple à la sortie d’un concasseur ou silo |

non | oui | oui | oui |

| Transfert des données de pesages par clé USB, format CSV | oui | non | oui | oui |

| Transfert des données de base et de pesages par Wifi de/vers Pfreundt Webportal | option | non | option | oui |

| Transfert des données de base et de pesages par GPRS de/vers Pfreundt Webportal | non | non | option | oui |

| Logiciel de pesage « commandes » pour l’exécution de commandes répétées | non | non | non | option |

| Revaloriser aux spécifications supérieures | – – | vers WK60-S | vers WK60 | – – |

| Les nombreuses possibilités sur WK60-XS, WK60-Smart, WK60-S et WK60 telles que décrites ci-dessus, peuvent être activées ou désactivées lors de l’installation afin de répondre au mieux à vos besoins. Notre valise de démonstration vous démontrera les nombreuses possibilités et la facilité d’usage. Demandez notre passage en vos bureaux, sans engagement. |

||||

Nederlands

Nederlands English

English